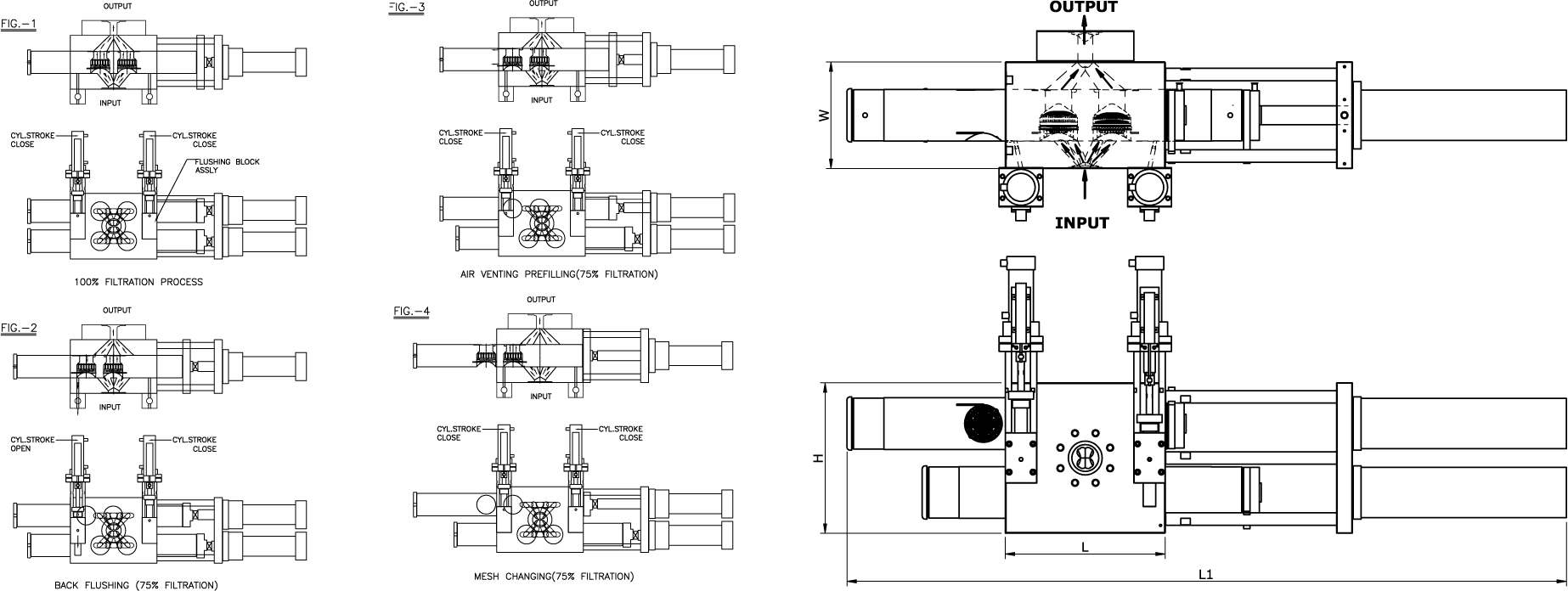

Founded in 1995 Rajhans Plastic machinery Pvt Ltd., holds the privilege of being the first company to introduce the concept of screen changer in India. We have already develop the double plunger with Back Flushing continuous screen changers but now this screen changer is equipped with two hydraulic cylinders. With this addition, the screen changer becomes a new design that is called Double Plunger with Automatic Back Flushing Continuous Screen changers. This helps enhance the quality, output and makes the operation fully-automatic. Supported by our strong team of qualified and experienced Engineering and Design Department, we now have a state-of-the-art infrastructure to produce 18 types of Screen Changers for different extrusion application. This helps us serve our clients in India and abroad better.

Applications:

- Recycling Plant

- Sheet Line Plant

- Monofilament Plant

- Staple Fibre Plant

- Compounding Plant

- Multifilament Plant

- Box Strapping Plant (PP/PET)

Features & Advantages of Auto Flushing

- By providing auto back flushing system, no manpower is required to open and clean flushing valve.

- With the help of pressure of input material and synchronizing with Hydraulic system, the flushing operation gets done automatically as per product material impurities.

- The product quality as well as quantity will increase significantly.

- Further, back flushing system and cycle can be established as per impurities / contamination of material.

- Due to auto back flushing, pressure and channel flow is maintained precisely.

- No operational involvement.

- Main advantage of this screen changer, 75% area of filtration will always be continuous after 100% filtration due to impurities.

- Heavy filtration area with non-stop production.

Installation support:

This Screen changer will be installed with barrel and die side adaptors, flanges

and PLC operating panel with linear scale fitted system. The non-stop

application/working including the system of pre-filling and air venting

operation.

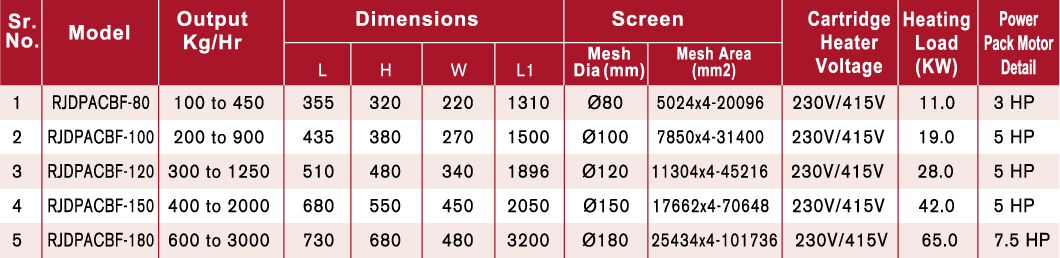

Technical Specifications